|

| September 06, 2016 | Volume 12 Issue 33 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

BMW intake system features DuPont Zytel PLUS nylon

The BMW Group's B58 3-liter straight-six gasoline engine features an integrated indirect charge air cooler from MAHLE. The system is made from DuPont Zytel PLUS nylon, which has particularly good resistance to heat and hot air aging.

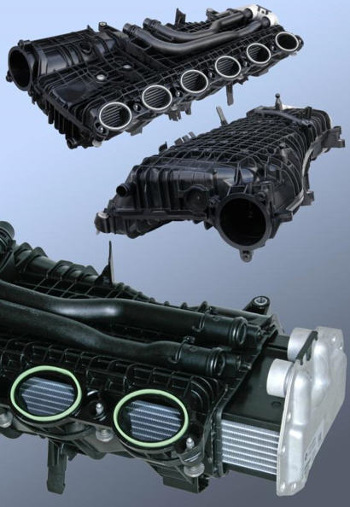

An intake system made from DuPont's Zytel PLUS nylon, with its good aging and temperature resistance, fitted with an integrated indirect charge air cooler from MAHLE, helps to optimize fuel/air mixture supply to BMW's new six-cylinder gasoline engines. [Photograph: DuPont]

The aluminum heat exchanger, through which coolant flows, is inserted lengthwise into the housing on guides that have sealing strips made from the same polymer. The innovative structural design of this charge air cooler means it can be arranged in the immediate vicinity of the engine, minimizing bulk and pressure drop and helping to optimize the balance of performance and fuel efficiency. The BMW Group has been using the B58 engine in its 740i, 440i, and 340i models since late 2015.

This innovative application has been jointly developed by a team from Mahle, BMW, and DuPont Performance Materials who selected the glass fiber-reinforced grade Zytel PLUS 95G35. This choice arose from the product's inherent outstanding resistance to chemicals and temperatures up to 230 deg C combined with very good weldability. For this application, high weldability, using friction welding, is particularly important given the large size of the upper and lower parts of the housing that are molded in one shot in an injection molding tool with a 1+1 cavity.

"By deciding on a glass fiber content of 35 percent by weight, we ensured a good balance of rigidity and impact strength," says Martin Valecka, development project manager at MAHLE. "This combination of properties meant we were able to provide numerous thin-walled but nevertheless highly effective supporting ribs. These ribs help to minimize deformation of the intake system even at high charge air pressures and temperatures and to ensure durability over the entire service life. Thanks to the very good flowability of Zytel PLUS, we can achieve short injection molding cycle times, despite sometimes narrow flow paths for these large-volume components. Good flow ability also better supports cost-effective manufacture."

Zytel PLUS is produced using DuPont's proprietary SHIELD technology, which combines an innovative polymer backbone architecture with specific polymer modifications and additives. Zytel PLUS 95G35 is the multipurpose product within this product family. Thanks to its very high heat resistance, it retains the majority of its mechanical properties even after 3,000 hours at 230 deg C, bearing in mind that the properties of conventional PA66-GF35 grades drop to below half their initial value at 180 deg C.

"The result of our joint collaboration with the BMW Group and MAHLE is a current example of how OEMs and tier-1 suppliers can benefit from our comprehensive product range and development abilities," says Dr. Olena Novikova, key account manager, DuPont Performance Materials. "Thanks to the SHIELD technology, components made from Zytel PLUS -- which are exposed to hot oil, hot air, coolant, and road salt -- can achieve a service life twice to three times that of parts made from conventional nylons. This resistance means the material is of interest for applications on the hot side of the air intake as well as for cylinder head covers, resonators, exhaust gas systems, and oil sumps. The plastic parts of MAHLE's integrated indirect charge air cooler can thus easily withstand the specified temperatures of -40 deg C to 190 deg C and exposure to blow-by and recirculated exhaust gases over the vehicle's entire service life."

Background on integrated indirect charged air cooling

Integrating indirect charged air cooling by means of liquid coolants offers considerable advantages over the conventional approach of directly cooling charged air with outdoor air. It permits the relocation of this cooling operation to the immediate vicinity of the engine as opposed to the front end of the vehicle. This results in:

- Saving space: The charged air is cooled close to the engine by a coolant that is in turn cooled by outdoor air in a separate low-temperature circuit. This low-temperature cooler is very compact and so saves front-end space. The bulky charge air hoses used in direct charge air cooling are replaced by thin coolant lines. There is no requirement for ducts between the charged air cooler and intake manifold.

- Boosting performance: Due to a smaller volume and short flow paths, the pressure drop is up to 80 percent lower than in conventional direct cooling. This translates into a higher volumetric efficiency in the cylinder. In addition, cooler air remains available to the engine for a longer time, for example under hard acceleration. Both factors have a positive impact on engine performance and responsiveness.

About the companies in this article

MAHLE is a leading international development partner and supplier to the automotive industry. With its products for combustion engines and their peripherals as well as solutions for electric vehicles, the group addresses all the crucial issues related to powertrain and air conditioning technology -- from engine systems and components to filtration to thermal management.

DuPont Performance Materials (DPM) is a leading innovator of thermoplastics, elastomers, renewably sourced polymers, high-performance parts and shapes, as well as resins that act as adhesives, sealants, and modifiers.

Source: DuPont Performance Materials

Published September 2016

Rate this article

View our terms of use and privacy policy